無縫管, 不銹鋼無縫管, 無縫不鏽鋼管(®DTI Cold Forged Bright Annealed Stainless Steel Tubing/Pipe)

Product ID: DTI-CFBA Tube

發送詢問Setting New Standard Archiving Tough Demands,

Pioneering Thinking for Top of the B.A.

Tubing by C.F.B.A Patent Process.

1. One D VS. 3D Quality.

People only care about tubing’s tradition quality (surface roughness Ra value of I.D. & O.D, material composition, dimensions, )

DTI also care about tubing’s inside material structure from the best grain structure, density & higher mechanical properties. (3D, care).

2. 30%H2+N2BA. VS. 100% H2 BA Process. Partial Recrystallization VS. Completed Recrystallization.

We use 100% H2 for our bright annealed process, without N2 pickup, without intergrnular corrsive with optimum metallurgical condition to enhance performance.

3. Quality VS. Consistent Quality. Brand New Quality VS. Years Quality. Bead Worked & Bead Reduced VS. Cold Forged.

In CFBA process, whole raw tube was forged and inside surface was forged into Ra≦12 µIn/0.3 µm or better. Without any mechanical polished, chemical polished or electro polished.

Regular tube/pipe might varyform batch to batch. Even single tube to tube. Consistent quality of cold forged. Complete reduced and proper bright annealing step are require for homogenization of tube. This tubing is true hight purity tubing.

Form the grain size of microstructure, {higher purity & corrosion resistance to higher density (hardest tempers /tensile/strength)are superior worldwide manufacture remain high weld ability (Creq/Nieq≧1.45)}.

商品規格

AP/BA/EP無縫不鏽鋼管 標稱管徑 Designator 外徑 O.D 厚度(SCH10) Thickness 重量(S10) Weight 厚度(CH20) Thickness 重量(S20) Weight 厚度(SCH40) Thickness 重量(S40) Weight 厚度(SCH80) Thickness 重量(S80) Weight 厚度(SCH160) Thickness 重量(S160) Weight lnch ASTM JIS mm kg/M mm kg/M mm kg/M mm kg/M mm kg/M 1/4 13.7 13.8 1.65 0.49 2.0 0.58 2.24 0.63 3.02 0.80 - - 3/8 17.1 17.3 1.65 0.64 2.0 0.76 2.31 0.85 3.20 1.11 - - 1/2 21.3 21.7 2.11 1.02 2.5 1.18 2.77 1.31 3.73 1.64 4.78 1.97 3/4 26.7 27.2 2.11 1.3 2.5 1.52 2.87 1.74 3.91 2.24 5.56 2.94 1 33.4 34 2.77 2.15 3.0 2.29 3.38 2.57 4.55 3.27 6.35 4.36 1-1/4 42.2 42.7 2.77 2.76 3.0 2.94 3.56 3.47 4.85 4.57 6.35 5.73 1-1/2 48.3 48.6 2.77 3.16 3.0 3.37 3.68 4.1 5.08 5.47 7.14 7.29 2 60.3 60.5 2.77 3.98 3.5 4.92 3.91 5.44 5.54 7.46 8.74 11.1 2-1/2 73 76.3 3.05 5.42 3.5 6.28 5.16 9.12 7.01 12.0 9.53 15.6 3 88.9 89.1 3.05 6.37 4.0 8.39 5.49 13.5 7.62 15.3 11.13 21.4 4 114.3 114.3 3.05 8.23 4.0 10.9 6.02 16 8.56 22.4 13.49 33.6 5 141.3 139.8 3.4 11.4 5.0 16.6 6.55 21.7 9.53 30.5 15.88 48.6 6 168.3 165.2 3.4 13.6 5.0 19.8 7.11 27.7 10.97 41.8 18.26 66 8 219.1 216.3 3.76 20.9 6.5 33.6 8.18 42.1 12.70 63.8 23.01 110 10 273 267.4 4.19 26 6.5 41.8 9.27 59.2 15.09 93.9 28.58 168 12 323.8 318.5 4.57 34.8 6.5 50.0 10.31 78.3 17.48 129 33.32 234 14 355.6 6.35 43.7 8.0 69.3 11.13 95.3 19.05 159 35.71 - 16 406.4 6.35 50 8.0 79.4 12.70 125 21.44 205 40.49 - 18 457.2 6.35 56.3 8.0 89.5 14.27 158 23.83 257 45.24 - 20 508 6.35 68.8 9.5 118 15.09 185 26.19 314 50.01 - 22 559 6.35 75.8 9.5 130 - 215 28.58 378 53.98 - 24 610 6.35 97.7 9.5 142 15.09 258 30.96 447 59.54 - 化學成分與特性 Chemical Compositions and Properties 鋼種 化學成分 (%) Chemical Composition 降伏強度 Y.S 抗拉強度 T.S 延伸率 E.L 斷面縮率 R of A 硬度 Hardness Grade C Si Mn Ni Cr Mo N/mm2 N/mm2 (%) (%) HB SS304 ≦0.08 ≦1 ≦2 8~10.5 18~20 - ≧205 ≧520 ≧35 ≧60 ≧187 SS304L ≦0.03 ≦1 ≦2 9~13 18~20 - ≧175 ≧480 ≧35 ≧60 ≧187 SS316 ≦0.08 ≦1 ≦2 10~14 16~18 2~3 ≧205 ≧520 ≧35 ≧60 ≧187 SS316L ≦0.03 ≦1 ≦2 10~15 16~18 2~3 ≧175 ≧480 ≧35 ≧60 ≧187 SS304H 0.04~0.1 ≦0.75 ≦2 8~11 18~20 - ≧205 ≧520 ≧35 - - SS321 ≦0.08 ≦1 ≦2 9~13 17~19 - ≧205 ≧520 ≧35 ≧50 ≧187 SS317L ≦0.03 ≦1 ≦2 11~15 18~20 3~4 ≧175 ≧480 ≧35 ≧60 ≧187 SS310S ≦0.08 ≦1.5 ≦2 19~22 24~26 - ≧205 ≧520 ≧35 ≧50 ≧187認證

- EJMA

- SEMI BPE 3A

主要產品

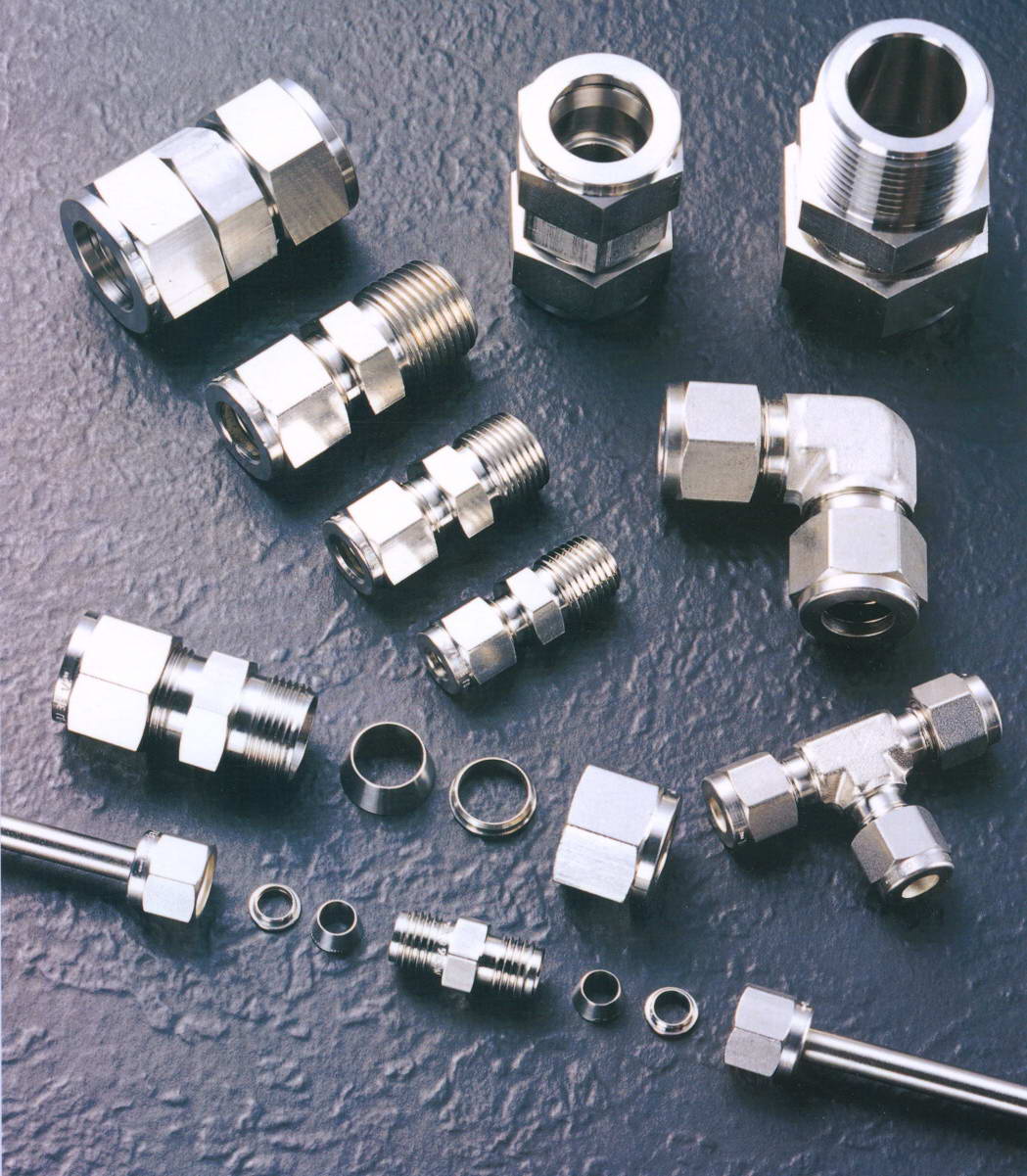

1.不銹鋼BA管/EP管, 不鏽鋼BA/EP管配件,無縫不鏽鋼管. 2.真空軟管, 真空管件, 真空閥門, 真空管束, 真空法蘭, 真空零件. 3.生技製藥BPE管件,BPE衛生級隔膜閥,衛生幫浦,食品管件,衛生管件,衛生軟管,衛生級過濾器. 4.半導體管件,Swagelok

同類型產品

聯絡資料

-

業務聯絡人陳小姐 / 詹小姐

-

地址241 新北市三重區光復路二段102巷1-2號

-

電話886-2-22783666

-

傳真886-2-85112456

-

電子郵件

-

網址

頂天鋼鐵有限公司

頂天鋼鐵有限公司